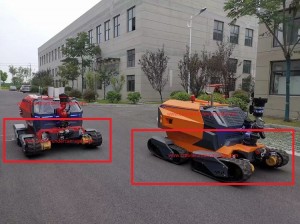

All-terrain four-drive firefighting robot undercarriage customized with grey or black frame

Product Description

All-terrain four- drive drive firefighting robot is a multi-functional firefighting robot, mainly used to fight fires that are inaccessible to personnel and conventional firefighting robots with complex terrain. The robot is equipped with fire smoke exhaust system and demolition system, which can effectively exclude smoke disaster at the fire relief site, and can remotely control the fire cannon to the required position using its own power. Replace fire fighters close to fire sources and dangerous places to avoid unnecessary casualties. It is mainly used for subway station and tunnel fire, large span, large space fire, petrochemical oil depot and refining plant fire, underground facilities and freight yard fire and dangerous fire target attack and cover.

The robot adopts a four- drive tracked chassis, which is flexible, can turn in place, climb, and has strong cross-country ability, and can easily cope with a variety of complex terrain and environment. Specifically, the role of the four- drive chassis on the firefighting robot includes:

1. Good traversability: The four- drive chassis allows the robot to have better traversability under different terrain conditions, including climbing hills, overcoming obstacles, crossing uneven terrain, etc., which is crucial for the movement of fire-fighting robots at fire scenes.

2. Stability: The four- drive chassis can provide better stability, allowing the robot to remain stable even on uneven ground, which is helpful for carrying equipment and performing tasks.

3. Carrying capacity: Four- drive chassis are usually designed as structures that can carry a certain weight, which means that firefighting robots can carry more equipment and tools, such as water guns, fire extinguishers, etc., to better perform firefighting tasks.

4. Flexibility: The four-wheel drive chassis can provide better maneuverability and flexibility, allowing the robot to quickly respond to the fire commander’s instructions and flexibly adjust its attitude and direction.

Therefore, the four- drive chassis is crucial to the role of the firefighting robot. It can provide the robot with stability, mobility and load-bearing capacity in complex environments, allowing it to better perform firefighting tasks.

Quick Details

| Condition | New |

| Applicable Industries | fire-fighting robot |

| Video outgoing-inspection | Provided |

| Place of Origin | Jiangsu, China |

| Brand Name | YIKANG |

| Warranty | 1 Year or 1000 Hours |

| Certification | ISO9001:2015 |

| Load Capacity | 1Tons |

| Travelling Speed (Km/h) | 0-4 |

| Undercarriage Dimensions(L*W*H)(mm) | 800X200X360 |

| Width of Steel Track(mm) | 200 |

| Color | Black or Custom Color |

| Supply Type | OEM/ODM Custom Service |

| Material | Steel and rubber |

| MOQ | 1 |

| Price: | Negotiation |

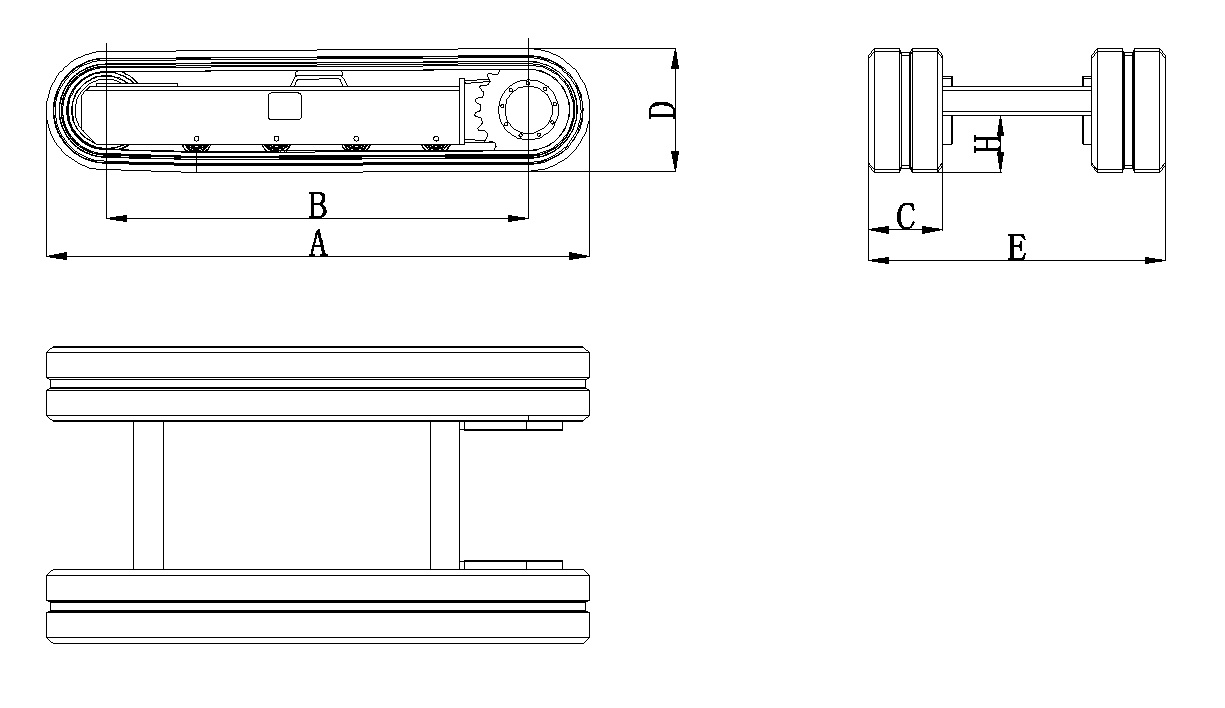

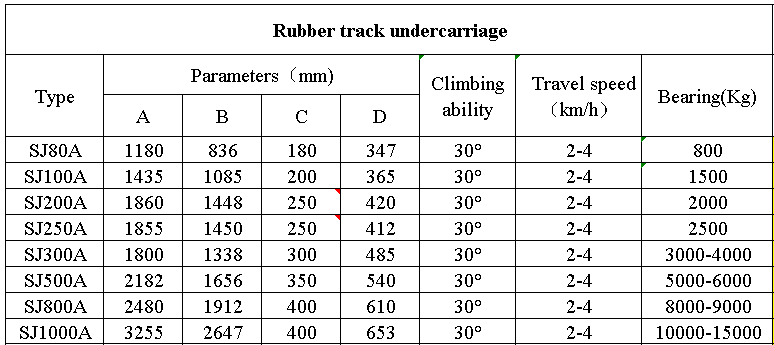

Yijiang company can custom Rubber and Steel Track Undercarriage for your machine

1. ISO9001 quality certificate

2. Complete track undercarriage with steel track or rubber track, track link , final drive, hydraulic motors, rollers, crossbeam.

3. Drawings of track undercarriage are welcome.

4. Loading capacity can be from 0.5T to 150T.

5. We can supply both rubber track undercarriage and steel track undercarriage.

6. We can design track undercarriage from customers’ requirements.

7. We can recommend and assemble the motor & drive equipment as customers’ requests. We can also design the whole undercarriage according to special requirements, such as measurements, carrying capacity, climbing etc. which facilitate the customers’ installation successfully.

Application Scenario

YIKANG complete undercarriages are engineered and designed in many configurations to serve a wide range of applications.

Our company designs, customizes and produces all kinds of steel track complete undercarriage for loads of 20 tons to 150tons. Steel tracks undercarriages are suitable for roads of mud and sand, stones rock and boulders , and steel tracks are stable on every road.

Compared with rubber track, rail has abrasion resistance and little risk of fracture.

Packaging & Delivery

YIKANG track undercarriage packing: Steel pallet with wrapping fill, or Standard wooden pallet.

Port: Shanghai or custom requirements

Mode of Transportation: ocean shipping, air freight, land transportation.

If you finish the payment today, your order will ship out within the delivery date.

| Quantity(sets) | 1 - 1 | 2 - 3 | >3 |

| Est. Time(days) | 20 | 30 | To be negotiated |

One- Stop Solution

Our company has a complete product category which means you can find everything you need here. Such as track roller, top roller, idler, sprocket, tension device, rubber track or steel track etc.

With the competitive prices we offer, Your pursuit is sure to be a time-saving and economic one.