Crawler undercarriage with rubber pads steel chains for mobile crushers drilling rig excavator

Product Description

1.What are the advantages of choosing Yijiang rubber tracked undercarriage?

Introducing our latest innovation in heavy machinery components: custom track undercarriages designed to increase equipment performance while maintaining factory price. At the intersection of durability and customization, our undercarriage solutions are tailored to meet the unique needs of your specific application, ensuring you get the most out of your machinery.

Our custom track undercarriages are precision engineered with high-quality materials to withstand harsh terrain and heavy loads. Whether you work in construction, mining or agriculture, our undercarriage systems are designed for enhanced stability and mobility, allowing your equipment to perform optimally in any environment.

What sets our products apart is the ability to custom design them to your operational needs. We know no two projects are the same, which is why we offer a range of options in track widths, lengths and material compositions. Our team of experts work closely with you to create a solution that not only perfectly fits your machine, but also optimizes its performance.

Additionally, we pride ourselves on offering factory prices without compromising on quality. By streamlining our manufacturing process and sourcing materials directly from trusted suppliers, we can save you significant costs. This means you can invest in a high-performance undercarriage without breaking the bank.

All in all, our custom track undercarriages are the perfect combination of custom design, rugged construction, and affordability. Upgrade your machine today and experience the difference a custom solution can make. With our commitment to quality and customer satisfaction, you can feel confident you’re making a wise investment in your equipment’s future. Contact us today to learn more about how we can help you achieve your operational goals!

2. What kind of machines can Yijiang rubber track undercarriage be used on?

More precisely, they can be put on the following kinds of machines in order to satisfy the various needs of consumers.

Excavators, loaders, bulldozers, various drilling rigs, firefighting robots, equipment for dredging rivers and seas, aerial working platforms, transportation and lifting equipment, prospecting machinery, loaders, static contactors, rock drills, anchor machines, and other large, medium, and small-sized machinery are all included in the category of construction machinery.

Equipment for agriculture, harvesters, and composters.

The YIJIANG business manufactures a wide variety of rubber crawler chassis that fit a variety of machinery types. extensively utilized in a variety of drilling rigs, field construction equipment, agricultural, gardening, and special operation machinery.

3. Why should I choose Yijiang rubber tracked undercarriage?

Zhenjiang Yijiang Machinery Co., Ltd. has been designing and manufacturing crawler undercarriages for 19 years. Clients from all around the world have used it to effectively complete the renovation and modernization of their machinery and equipment.

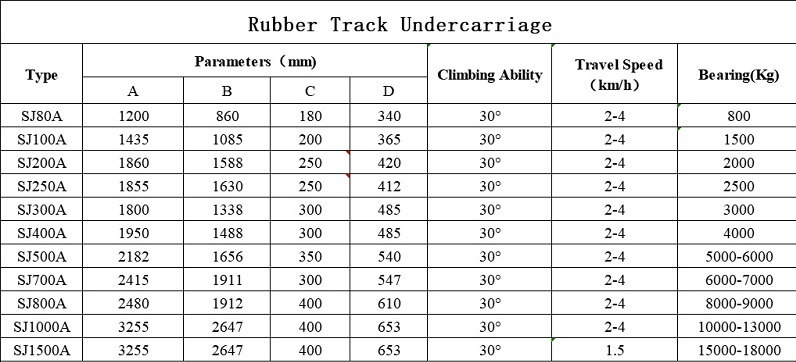

Yijiang rubber track undercarriage can support loads ranging from 500 kg to 30 tons. A plethora of styles and drawings are available for selection, and chassis specs can also be supplied. Our engineering staff will meticulously plan, create designs, and build a special chassis to fulfill your desire to be able to travel the world with your machine.

4. What parameters are provided that will facilitate the rapid delivery of your order?

In order to recommend a suitable drawing and quotation to you , we need to know:

a. Rubber track or steel track undercarriage, and need the middle frame.

b. Machine weight and undercarriage weight.

c. Loading capacity of the track undercarriage ( the weight of the whole machine excluding of track undercarriage).

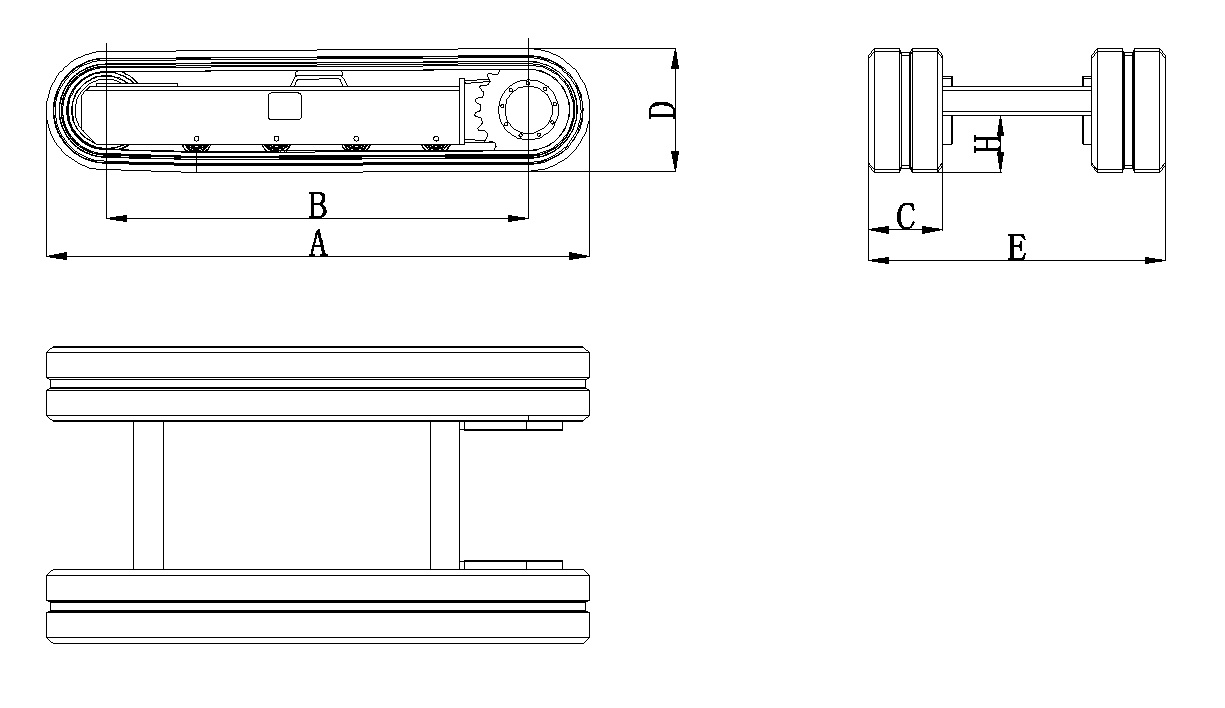

d. Undercarriage’s length, width and height

e. Track’s Width.

f. The max speed (KM/H).

g. Climbing slope angle.

h. The machine’s apply range , working environment.

i. Order quantity.

j. Port of destination.

k. Whether you require us to purchase or collocate relevant motor and gear box or not, or other special request.

Application Scenario

YIKANG complete undercarriages are engineered and designed in many configurations to serve a wide range of applications.

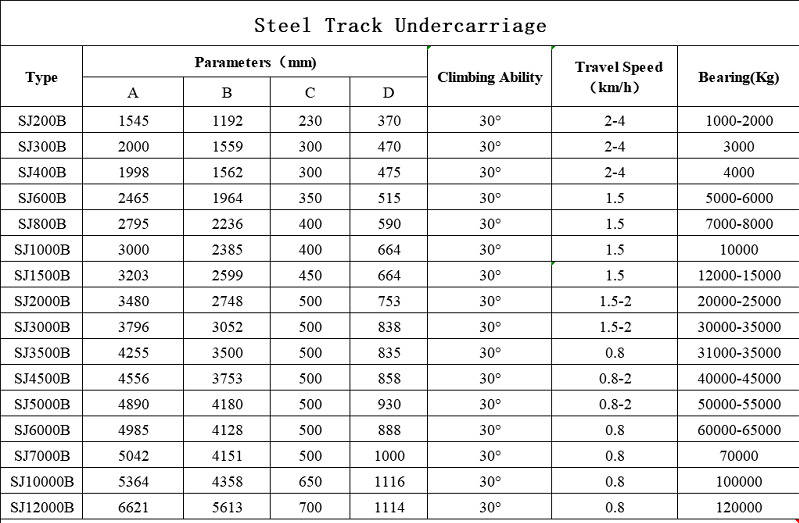

Our company designs, customizes and produces all kinds of steel track complete undercarriage for loads of 20 tons to 150tons. Steel tracks undercarriages are suitable for roads of mud and sand, stones rock and boulders , and steel tracks are stable on every road.

Compared with rubber track, rail has abrasion resistance and little risk of fracture.

Customized packing and shipping

YIKANG track undercarriage packing: Steel pallet with wrapping fill, or Standard wooden pallet.

Port: Shanghai or custom requirements

Mode of Transportation: ocean shipping, air freight, land transportation.

If you finish the payment today, your order will ship out within the delivery date.

| Quantity(sets) | 1 - 1 | 2 - 3 | >3 |

| Est. Time(days) | 20 | 30 | To be negotiated |

Yijiang company can custom Rubber and Steel Track Undercarriage for your machine

1. ISO9001 quality certificate

2. Complete track undercarriage with steel track or rubber track, track link , final drive, hydraulic motors, rollers, crossbeam.

3. Drawings of track undercarriage are welcome.

4. Loading capacity can be from 0.5T to 150T.

5. We can supply both rubber track undercarriage and steel track undercarriage.

6. We can design track undercarriage from customers’ requirements.

7. We can recommend and assemble the motor & drive equipment as customers’ requests. We can also design the whole undercarriage according to special requirements, such as measurements, carrying capacity, climbing etc. which facilitate the customers’ installation successfully.