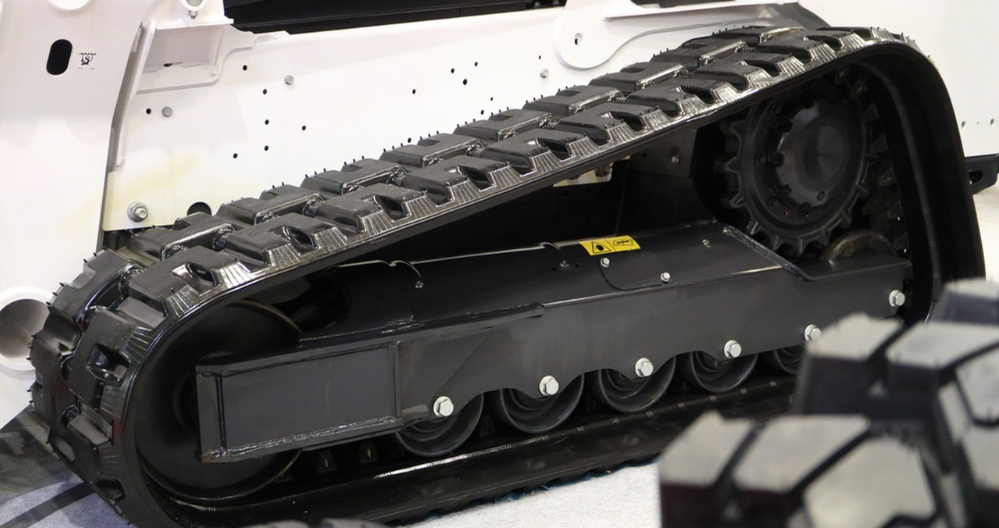

When it comes to heavy construction equipment, it is essential to ensure that they are manufactured from durable materials that can withstand the harsh conditions they are exposed to. Rubber tracked undercarriages provide the perfect solution for construction equipment. Rubber track undercarriages provide a stable platform for heavy machinery such as excavators, bulldozers and trenchers. They offer many advantages over traditional steel track systems.

This article will explore the various benefits of using Rubber track undercarriages in construction equipment.

1. Improved mobility

The rubber track undercarriage provides excellent maneuverability compared to steel track systems. The rubber track is more flexible and can run smoothly on rough terrain. They provide better traction and stability, enabling heavy machinery to work safely in challenging conditions such as muddy environments or uneven terrain.

Rubber tracks also reduce ground impact while keeping equipment level for more stable and efficient operation. They also provide a smoother ride, reduce operator fatigue and improve overall performance.

2. Reduce noise

One of the significant advantages of using rubber tracked undercarriages is that they produce less noise than steel tracked systems. Rubber tracks absorb vibrations, reducing noise levels and making the job site more comfortable. The reduced noise level also allows the machinery to work in residential areas without disturbing the surrounding community.

3. Increase mobility

Rubber track undercarriages make moving heavy machinery easier than steel track systems. The track maintains a consistent speed regardless of the terrain, providing smooth and consistent movement. The enhanced maneuverability enables the equipment to operate in tight spaces, increasing the overall efficiency of the equipment.

4. Reduce maintenance costs

Rubber track undercarriages systems require less maintenance than steel track systems, which are more prone to wear and tear. The rubber tracks are durable and can withstand heavy loads without damaging the machine. This significantly reduces repair and replacement costs over the life of the machine.

5. Better fuel efficiency

Rubber tracks are lightweight, which means less power is required to move them, improving fuel efficiency. They also have a larger contact area with the ground, which reduces drag and drag on equipment, which improves fuel efficiency.

6. Increased security

Rubber track undercarriages provide increased safety compared to steel track undercarriages. Tracks are less likely to cause soil erosion or damage, reducing the risk of accidents on the job site. The rubber tracks also provide better traction, which increases the stability and control of the equipment, reducing the risk of accidents.

7. Environmental protection has been improved

Rubber track undercarriage systems are a more environmentally friendly option than steel track systems. They reduce soil damage even more significantly and thus improve environmental protection. The reduced noise pollution also makes them more environmentally friendly.

Rubber track undercarriages offer a wide range of benefits, from increased safety and mobility to reduced maintenance costs and improved fuel efficiency. Rubber tracks absorb vibrations for a more comfortable working environment and reduce noise levels, making it more efficient to operate in residential areas.

Environmental benefits such as reduced soil erosion, improved fuel efficiency and reduced noise pollution make rubber track undercarriages a greener choice. Collectively, these advantages make rubber track undercarriages an ideal solution for heavy construction equipment requiring a stable and efficient platform for optimum performance.