Products

-

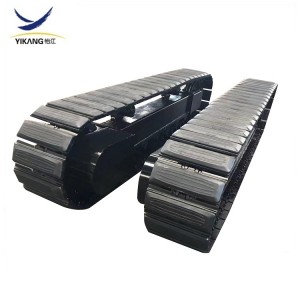

Steel track undercarriage with rubber pads for mobile crusher drilling rig

Yijiang company can custom tracked undercarriage for construction machinery. The production process is carried out in strict accordance with the technical standards of machining and manufacturing, and the quality level is high.

The product is designed for mobile crusher/drilling rig,the specific parameters are as follows:

Type: custom multifunctional application

Load capacity: 20 tons

Size: 4570mm x 500mm x 760mm

Product origin: Jiangsu,China

Brand: YIKANG

Delivery time: 35 days

-

Factory custom rubber track undercarriage with middle crossbeam for drilling rig transport vehicle

Yijiang company can custom tracked undercarriage for construction machinery. The production process is carried out in strict accordance with the technical standards of machining and manufacturing, and the quality level is high.

The product is designed for drilling rig/transport vehicle,the middle structural parts can be customized according to your requirements.

The specific parameters are as follows:

Type: custom multifunctional application

Load capacity: 6.5 tons

Size: 2800mm x 1850mm x 500mm

Product origin: Jiangsu,China

Brand: YIKANG

Delivery time: 30 days

-

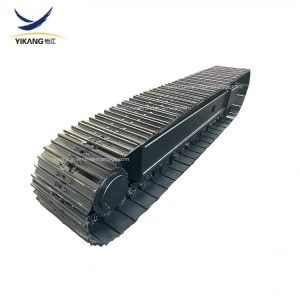

Drilling rig parts steel track undercarriage for 15-150 tons heavy crawler machinery

Yijiang company can custom tracked undercarriage for construction machinery. The production process is carried out in strict accordance with the technical standards of machining and manufacturing, and the quality level is high.

The product is designed for drilling rig,specific parameters are as follows:

Load capacity: 35 tons

Size: 4300mm x 500mm x 768mm

Weight: 5 tons

Product origin: Jiangsu,China

Brand: YIKANG

Delivery time: 30 days

-

China custom new drilling rig undercarriage platform for your crawler machinery vehicle

1. Custom type undercarriage, middle crossbeam can be designed according to your requirements

2. For transport vehicle / drilling rig in special working condition

3. Load capacity is 4.5 tons, and the size is 2850*1410*500mm

4. The production process is carried out in strict accordance with the technical standards of machining and manufacturing, and the quality level is high.

-

Factory custom new steel track undercarriage for transport vehicle drilling rig with high quality

1. Custom type undercarriage, middle croaabeam can be designed according to your requirements

2. For transport vehicle / drilling rig in special working condition

3. Load capacity is 700kg, and the size is 1500*800*350mm

4. The production process is carried out in strict accordance with the technical standards of machining and manufacturing, and the quality level is high.

-

Spider lift parts hydraulic rubber track undercarriage for 2 tons multifunctional crane lift robot

1. Designed for spider lift /crane/robot

2. Crawler undercarriage can provide functions such as support, stability, traction, propulsion, flexibility and adaptability, allowing the spider to travel and operate in various complex working environments.

3. This chassis design is to improve the mobility, safety and efficiency of mechanical equipment while reducing the impact on the ground.

-

Custom crawler tracked undercarriage for heavy machinery such as excavators tractors bulldozers

The crawler undercarriage is a key component of heavy machinery such as excavators, tractors, and bulldozers. It plays a vital role in providing these machines with maneuverability and stability, allowing them to operate effectively in a variety of terrains and conditions.

-

excavator drilling crawler tracked undercarriage manufacturers from China Zhenjiang Yijiang Company

Yijiang team of experts is dedicated to working closely with our customers to understand their unique needs and deliver custom solutions that exceed expectations. We pride ourselves on providing exceptional products and services that set new standards in the industry.

-

Customized crawler track undercarriage for drilling rig by professional manufacturer Yijiang company

As a professional manufacturer of customized undercarriage, yijiang company custom crawler track undercarriage for track drill rigs are ideal for those who require exceptional performance, durability and reliability. With our commitment to excellence, you can trust that our chassis will meet and exceed your expectations, ensuring the success of your drilling operations.

-

China Manufacturer Mini Excavator Truck Platform Crawler Chassis Rubber Track Undercarriage

The rig undercarriage with steel tracks is a vital asset to any drilling operation. Our products are designed to withstand the harshest conditions and provide maximum efficiency and safety during operation. We are confident that you will be satisfied with your purchase and our landing gear will exceed your expectations.

-

rubber track undercarriage system manufacturers for sale crawler drilling rig

One of the key benefits of a custom tracked undercarriage is its ability to ensure optimal performance in a variety of terrains and working conditions. Whether navigating the rough terrain of a construction site or working in muddy or snowy conditions in agriculture or forestry, a custom tracked undercarriage allows equipment to be equipped with the right features and components for efficient operation. This not only increases productivity but also reduces wear and tear on the equipment, thereby lowering maintenance costs and extending the service life of the equipment.

-

Platform Type Rubber Steeltracked undercarriage System manufacturers

Yijiang is proud of its reputation for providing reliable, durable custom track undercarriage solutions. Our track record speaks for itself, we have established a strong track record of delivering top quality undercarriage solutions to customers around the world. When you choose Yijiang, you choose a trusted partner dedicated to providing excellence in every aspect of our work.