Zhenjiang Yijiang Machinery Co.,Ltd

UmkhandiIkhareji yangaphantsiIncwadi yoLungiso

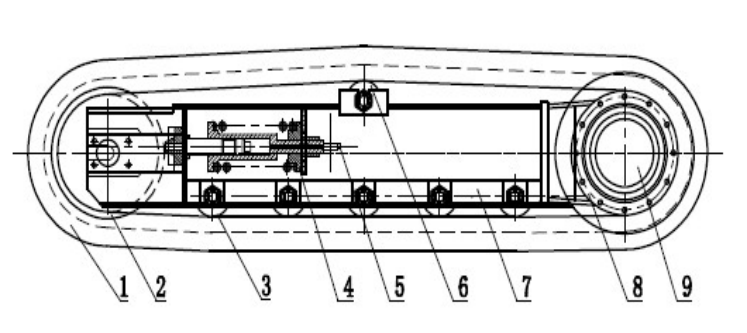

1. ukulandelela indibano 2. IDLER3. ukulandelela i-roller 4. isixhobo soxinzelelo 5. indlela yokulungelelanisa intambo 6.TOP ROLLER7. isakhelo somkhondo 8. ivili lokuqhuba 9. isinciphisi sesantya sokuhamba (igama eliqhelekileyo: ibhokisi yokunciphisa isantya semoto)

Iingoma ezisekhohlo nasekunene ziqhutywa ziimotor ezihamba ngasekhohlo nasekunene zehydraulic motors ukuqhuba iibhokisi zegiya ezihamba ngasekhohlo nasekunene ngokulandelelanayo, ukuqhuba iindlela zokuhamba.

(1)Track iindibano(kubandakanywa iindibano zomkhondo wentsimbi kunye neendibano zomkhondo werabha)

1: 1 Indibano yentsimbi yentsimbi yenziwe ngentsimbi yokuqina ephezulu eyenziwe yinkqubo ekhethekileyo yonyango lobushushu, ebonisa ukuxhathisa okuqinileyo, ubomi benkonzo ende kunye namandla aphezulu.

1:2 I-Rubber Track Assembly, umkhondo weRubber yibhande lerabha elimile okwesangqa elenziwe ngerabha edityaniswe nentsimbi okanye imathiriyeli yefiber. Izilumkiso zokusetyenziswa: umatshini kufuneka uphetshwe ukuqalisa okanye ukujika ngokukhawuleza kwiindawo ezibukhali neziphumayo. Musa ukuvumela umphezulu werabha ukuba udibane neoyile, sula ioyile ngokukhawuleza ukuba ikhona, kwaye ugweme iingoma ezidibana nezinye iindawo kumatshini, ngakumbi imiphetho yangaphakathi. Musa ukusebenzisa amavili okuqhuba kakubi, kuya konakalisa amazinyo entsimbi emizila. Xa umatshini ungasebenzi ixesha elide, iingoma zerabha kufuneka zisuswe kwaye zicocwe ukungcola kunye nezinye izinto, ukuphepha ilanga nemvula. Njengoko ziyimveliso yerabha, iingoma zerabha zisetyenziswa ngokubanzi kumaqondo obushushu ukusuka ku -25° ukuya kuma-55°.

1:3 Ukusetyenziswa kumashishini akhethekileyo, njengalawo asebenza phantsi kwamanzi olwandle, apho iityuwa ezahlukahlukeneyo zichithwa kunye nee-ion ezahlukeneyo ezikhoyo, ezibangelwa i-oxidising kunye nokunciphisa iipropati. Iyingozi kakhulu kwirabha okanye kwintsimbi. Okwangoku, phantsi kwesiseko sokungabikho kwenkxaso yedatha ehambelanayo, irabha ilandelela iwaranti yesiqingatha sonyaka okanye iiyure ezingama-500, kwaye emva koko ihlengahlengiswe ngokuhambelana nokusetyenziswa kwemeko. Kufuneka kugxininiswe ukuba, kungakhathaliseki ukuba i-chassis yirubha okanye intsimbi, kufuneka ihlanjululwe ngamanzi amatsha ngokukhawuleza emva kokushiya amanzi olwandle!

(2)IDLER, TRACK ROLLER

Iimeko zokusebenza ze-IDLER kunye ne-TRACK ROLLER zinzima kakhulu, azithwali ngokuthe ngqo ubunzima bomatshini, kodwa zithwala umthwalo wempembelelo enobudlova kwi-plate yesiseko. Ngamanye amaxesha i-TRACK ROLLER kufuneka ithwale isiqingatha sobunzima bomatshini wonke. Ngenxa yendawo ephantsi yokufakela i-TRACK ROLLER, sele ikwigrabile kunye ne-magma ixesha elide, kwaye ixhomekeke ekugqokeni okunzulu kunye nokukrazula. Ngoko ke, iindawo zokusebenza ze-track roller, i-IDLER kunye ne-TRACK ROLLER zenziwe lukhuni ngokuqiniswa kwe-medium-frequency. I-TRACK ROLLER, TOP ROLLER kunye ne-IDLER zitywinwe ngamatywina e-oyile adadayo kwaye zithanjiswa ngegrisi. Xa ujikeleza, esinye isiphelo seseyile esidadayo asishukumi, kwaye esinye isiphelo sesangqa setywina esidadayo sijikeleza kunye nevili, ngoncedo loxinzelelo lwe-O-ring, ukuze isiphelo setywina ezimbini ezidadayo sigqibe umphezulu. , ukufezekisa itywina. Isitywina se-oyile edadayo sithembekile, ngokuqhelekileyo kwixesha lokulungiswa akufuneki ukuba ugcwalise i-roller yomzila, i-IDLER kunye ne-TRACK ROLLER.

(3)TOP ROLLER

I-TOP ROLLER yilungu eliphambili lamandla omzila, kwaye iingxaki zokugqoka kunye namandla zivelele xa usebenza phantsi kweemeko ezinamatye kunye namanzi. I-TOP ROLLER yintsimbi ephezulu ye-carbon alloy ene-medium frequency quenching phezu komhlaba, enokumelana okugqwesileyo kokunxiba.

(4)Uxinzelelo lweengoma(yerabha kunye neengoma zentsimbi)

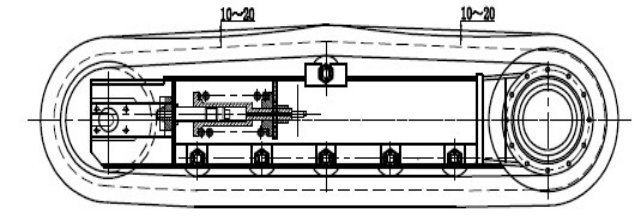

Ubomi bomzila wetsheyini kaninzi buxhomekeke kwiqondo lokuxinana kwengoma kunye nokuba uhlengahlengiso lufanelekile, ngoko ke jonga iqondo lokuxinana kwengoma rhoqo kwiiyure ezingama-30. Umgangatho wokuqina komzila: qala ucoce umzila, uphakamise umzila wensimbi okanye umzila werabha ngesandla, kunye nokuphakama kokuphakama malunga ne-10cm kuthathwa njengento eqhelekileyo. Xa ulungelelanisa ukuqina komzila, musa ukuwulungisa kakhulu okanye uqine kakhulu, kufuneka ube yimodareyitha, umzila unzima kakhulu, uya kuchaphazela isantya sokuhamba kunye namandla okuhamba, kwaye kuya kwandisa ukunxiba kunye nokukrazula phakathi kwendawo nganye, ukuba ilungelelaniswe ngokukhululekileyo, umkhondo okhululekileyo uya kubangela ukuguga okukhulu kunye nokukrazula kwivili lokuqhuba kunye nesondo lokutsala. Isixhobo soxinzelelo lwengoma siquka i-hydraulic tensioning kunye nokulungelelanisa.

Umzobo we-2 Umzobo weSchematic of track tensioning (indlela yokulungelelanisa yolohlobo lohlengahlengiso lwentambo)

(4.1) Inkqubo ethile yokusebenza yendlela yokulungelelanisa intambo: emva kokuvula i-nameplate kumqadi ophambili kwicala langaphandle lomkhondo, sebenzisa i-wrench evulekileyo ukujikeleza i-screw yokulungelelanisa i-hexagonal kwaye ugcine isalathiso sokuhamba kwe-IDLER, nge IDLER isiya phambili ukuze indlela iqiniswe kwaye i-IDLER ibuyela ngasemva ukuze indlela icutheke.

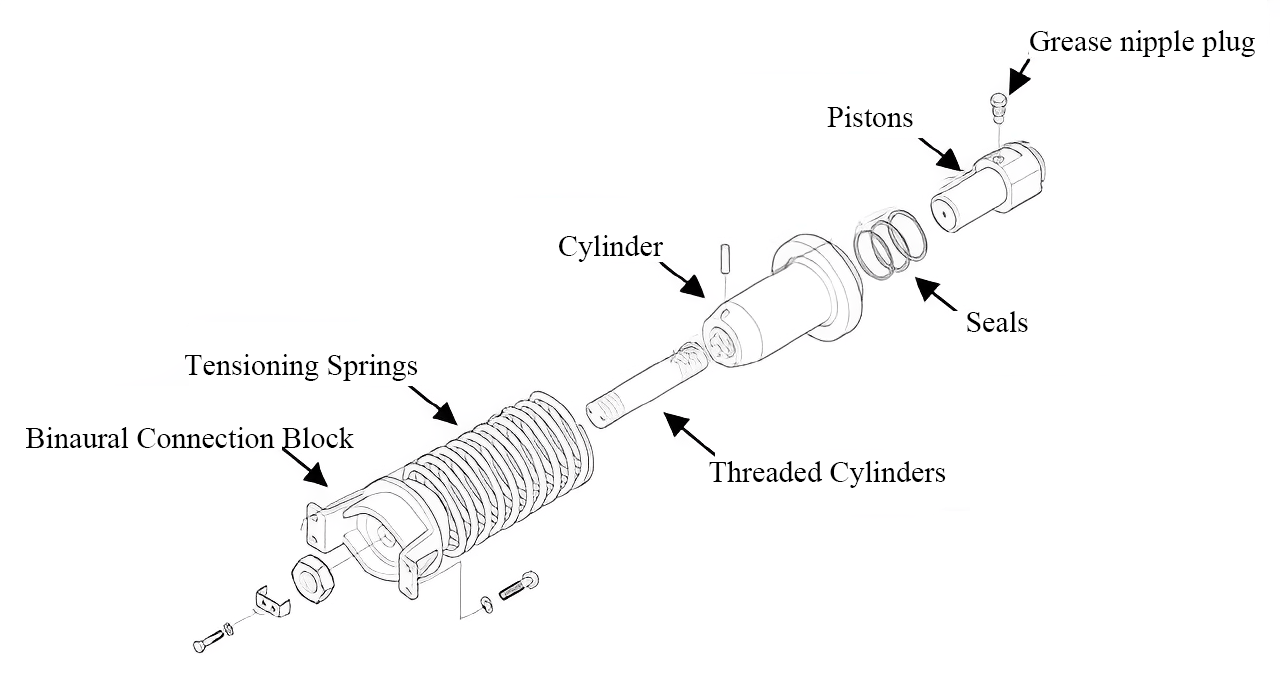

(4.2) Inkqubo ethile yokusebenza yokuqina kwe-hydraulic: emva kokuvula i-nameplate kumqadi ophambili kwicala langaphandle lomzila, i-valve yokukhangela igrisi ingono inokubonwa, ukuba ukuphakama kokuphakanyiswa komzila ngu> 3cm, sebenzisa umpu wegrisi. ukubamba ingono yegrisi yevalve ukuze igalelwe amafutha. Ukuba ukuphakama kokuphakamisa komzila ngu <3cm, khulula i-grease nipple kwi-1-2 ukujika, kwaye umzila uya kuthotywa ukuba kukho ukuphuphuma kwegrisi, sebenzisa indlela ekhankanywe ngaphambili ukuphakamisa umzila ngesandla ukuze ukhangele ukukhulula kunye. ukuqiniswa komzila (oqhotyoshelwe kulo mfanekiso ulandelayo ukuqinisa i-grease nipple). Okokuqala khulula i-cylinder grease nipple 1 ukuya ku-2 ujika, i-cylinder cylinder grease discharge, intonga ye-cylinder ihlehlisiwe. Emva koko qinisa i-grease ingono, uze udibanise igrisi entsha, khangela ukuba umphezulu wentonga ye-cylinder ayiqhelekanga, kwaye ukuba kuyimfuneko, sebenzisa igrisi kwintonga ye-cylinder, uze ugqibezele ukugcinwa kokunyuka kunye nokuqinisa i-cylinder (umfanekiso oqhotyoshelweyo 3).

(Umzobo 3 Umzobo weSchematic of hydraulic tightening (uhlobo lohlengahlengiso lokuqina koxinzelelo lwehydraulic)

(4.3): ukuba i-chassis isetyenziswa rhoqo, yongeza ioli kanye emva kweenyanga ezintandathu okanye njalo, kwaye udibanise i-90 # i-oyile yegiya kwi-TOP ROLLER kunye ne-roller yomzila (yongeza i-oyile ngomngxuma weplagi ye-oyile kumzimba wevili).

(5) Nceda ubhekisele kwincwadana yemiyalelo yokusetyenziswa kwebhokisi yegiya yokunciphisa ukuhamba (incanyathiselwe).

(6) Nceda ugcine indibano ye-chassis icocekile, xa ingasetyenziswa, nceda uyibeke kwindawo epholileyo neyomileyo, uthintele ukukhanya kwelanga nemvula. Ngexesha lokusebenza, jonga inkangeleko ye-chassis ye-crawler yonke imihla, kwaye uhlale ujonga iibholithi zokudibanisa kwivili lokuqhuba kunye ne-gearbox yonke imihla, kwaye uziqinise ngexesha xa zifunyenwe zikhululekile. Ngexesha lokusetyenziswa, nceda ubeke ingqalelo kwisantya somatshini, isantya esiphantsi, ungagqithisi isantya kunye nomthwalo ogqithisileyo. Emva kokuba amanzi olwandle okanye amanzi e-alkaline ephuma, ngokukhawuleza uwahlambe ngamanzi acocekileyo. Emva kokusetyenziswa kwindawo yokwakha, hlambulula ngokukhawuleza ukucima i-silt, ucoce i-samente, gcina ucocekile !!!!

Ixesha lokuposa: Feb-08-2024