I-Zhenjiang Yijiang Machinery Co., Ltd

UmgadliI-UndercarriageImanuwali Yesondlo

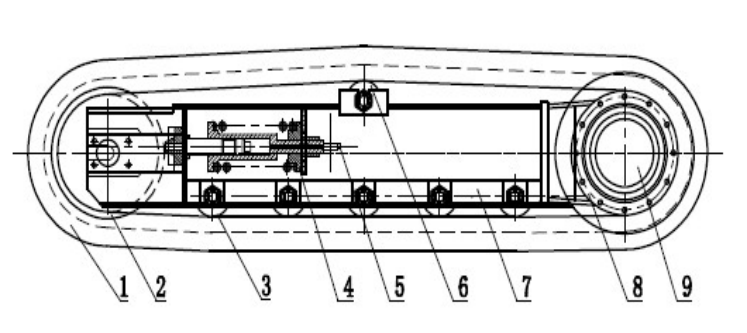

1. ithrekhi yokuhlanganisa 2. IDLER3. ithrekhi roller 4. i-tensioning device 5. indlela yokulungisa intambo 6.I-ROLLER ephezulu7. i-track frame 8. isondo lokushayela 9. isinciphisi sesivinini esihambayo (igama elivamile: ibhokisi le-motor speed reducer)

Amathrekhi angakwesokunxele nakwesokudla ashayelwa ama-hydraulic motors ahamba kwesokunxele nakwesokudla ukushayela ama-gearbox ahamba kwesokunxele nakwesokudla ngokulandelana, ukushayela amathrekhi ukuhamba.

(1)Landelela imihlangano(okuhlanganisa ama-steel track assemblies nama-rubber track assemblies)

1:1 Umhlangano wethrekhi wensimbi wenziwa ngensimbi eqinile ye-alloy eyakhiwe inqubo ekhethekile yokwelapha ukushisa, efaka ukumelana nokugqokwa okuqinile, impilo ende yesevisi namandla aphezulu.

1:2 I-Rubber Track Assembly, ithrekhi yerabha ibhande lenjoloba elimise okwendandatho elenziwe ngerabha elihlanganiswe nensimbi noma impahla yefiber. Izinyathelo zokuphepha zokusetshenziswa: umshini kufanele ugwenywe ukuqala noma ukujika ngokushesha ezindaweni ezicijile neziphumela ngaphandle. Ungavumeli indawo yenjoloba ukuthi ihlangane namafutha, sula amafutha ngokushesha lapho ekhona, futhi ugweme amathrekhi ukuthintana nezinye izingxenye emshinini, ikakhulukazi emaphethelweni angaphakathi. Ungasebenzisi amasondo okushayela aguge kabi, azolimaza amazinyo ensimbi amathrekhi. Uma umshini ungasebenzi isikhathi eside, amathrekhi enjoloba kufanele asuswe futhi ahlanzwe ukungcola nezinye izinto, ukugwema ilanga nemvula. Njengoba kuyimikhiqizo yenjoloba, amathrekhi enjoloba ngokuvamile asetshenziswa emazingeni okushisa asukela ku -25° ukuya ku-55°.

1:3 Ukuze kusetshenziswe ezimbonini ezikhethekile, njengalezo ezisebenza ngaphansi kwamanzi olwandle, lapho usawoti ohlukahlukene uncibilika khona futhi ama-ion ahlukahlukene akhona, okuholela ekusetshenzisweni kwe-oxidising nokunciphisa izakhiwo. Iyingozi kakhulu enjolweni noma ensimbi. Njengamanje, ngaphansi kwesisekelo sokuthi akukho ukusekelwa kwedatha okuhambisanayo, iwaranti yamathrekhi erabha ingxenye yonyaka noma amahora angama-500, bese ilungiswa ngokuya ngokusetshenziswa kwesimo. Kufanele kugcizelelwe ukuthi, kungakhathaliseki ukuthi i-chassis iyirabha noma insimbi, kufanele igezwe ngamanzi ahlanzekile ngokushesha ngemva kokushiya amanzi olwandle!

(2)IDLER, TRACK ROLLER

Izimo zokusebenza ze-IDLER kanye ne-TRACK ROLLER zinzima kakhulu, azigcini nje ngokuthwala isisindo somshini ngokuqondile, kodwa futhi zithwala umthwalo onobudlova ovela ku-base plate. Kwesinye isikhathi i-TRACK ROLLER kufanele ithwale uhhafu wesisindo somshini wonke. Ngenxa yesimo esiphansi sokufakwa kwe-TRACK ROLLER, isihlale kugraveli ne-magma isikhathi eside, futhi ingaphansi kokuguga okukhulu. Ngakho-ke, izindawo zokusebenza ze-track roller, i-IDLER ne-TRACK ROLLER zenziwe lukhuni ukuqina kwe-medium-frequency. I-TRACK ROLLER, TOP ROLLER kanye ne-IDLER zivalwa ngezigxivizo zikawoyela ezintantayo futhi zigcotshwe ngamafutha. Lapho izungeza, ingxenye eyodwa yendandatho entantayo yophawu ayinyakazi, kanti enye indandatho yendandatho entantayo izungeza nesondo, ngosizo lokuqina kwe-O-ring, ukuze indandatho yophawu entantayo iphele ukucindezelwa kwendawo. , ukufeza uphawu. Isigxivizo sikawoyela esintantayo sithembekile, imvamisa esikhathini sokushintsha akudingi ukufaka uphethiloli kwirola yethrekhi, i-IDLER ne-TRACK ROLLER.

(3)I-ROLLER ephezulu

I-TOP ROLLER iyilungu lamandla amakhulu ethrekhi, futhi izinkinga zokuguga namandla zibonakala uma usebenza ngaphansi kwezimo ezinamatshe namanzi. I-TOP ROLLER iyinsimbi ephezulu ye-carbon alloy ene-medium frequency quenching ebusweni, enokumelana okuhle kakhulu kokugqoka.

(4)Ukuqina kwamathrekhi(amathrekhi erabha nensimbi)

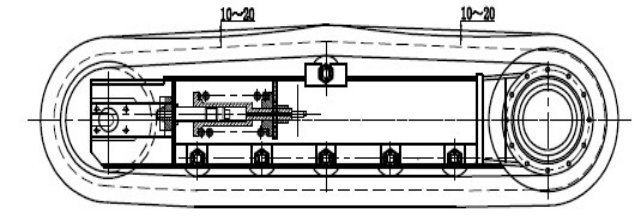

Impilo yethrekhi yochungechunge kuvame ukuncika ezingeni lokushuba kwethrekhi nokuthi ukulungisa kunengqondo, ngakho hlola izinga lokushuba kwethrekhi njalo emahoreni angama-30. Izinga lokuqina kwethrekhi: hlanza kuqala ithrekhi, phakamisa ithrekhi yensimbi noma ithrekhi yerabha ngesandla, futhi ukuphakama kokuphakamisa okungaba ngu-10cm kuthathwa njengokujwayelekile. Uma ulungisa ukucinana kwethrekhi, ungayilungisi ixege kakhulu noma iqine kakhulu, kufanele ibe maphakathi, ithrekhi iqine kakhulu, izophazamisa isivinini sokuhamba namandla okuhamba, futhi kuzokwandisa ukuguga phakathi kwengxenye ngayinye, uma ilungiswa ngokuxekethile, ithrekhi exegayo izodala ukuguga nokudabuka kwesondo lokushayela kanye nesondo lokudonsa. Idivayisi yokuqinisa ithrekhi iqukethe i-hydraulic tensioning kanye nendlela yokulungisa.

Fig. 2 Umdwebo ohleliwe wokuqina kwethrekhi (indlela yokulungisa iwuhlobo lokulungiswa kwentambo)

(4.1) Inqubo eqondile yokusebenza yendlela yokulungisa intambo: ngemva kokuvula i-nameplate kubhamu eyinhloko ohlangothini olungaphandle lwethrekhi, sebenzisa isikrufu esivulekile ukuze uphendukise isikulufu sokulungisa esiyi-hexagonal futhi ubheke isiqondiso sokunyakaza kwe-IDLER, nge-IDLER eya phambili ukuze ithrekhi iqiniswe kanye ne-IDLER eya emuva ukuze ithrekhi inciphe.

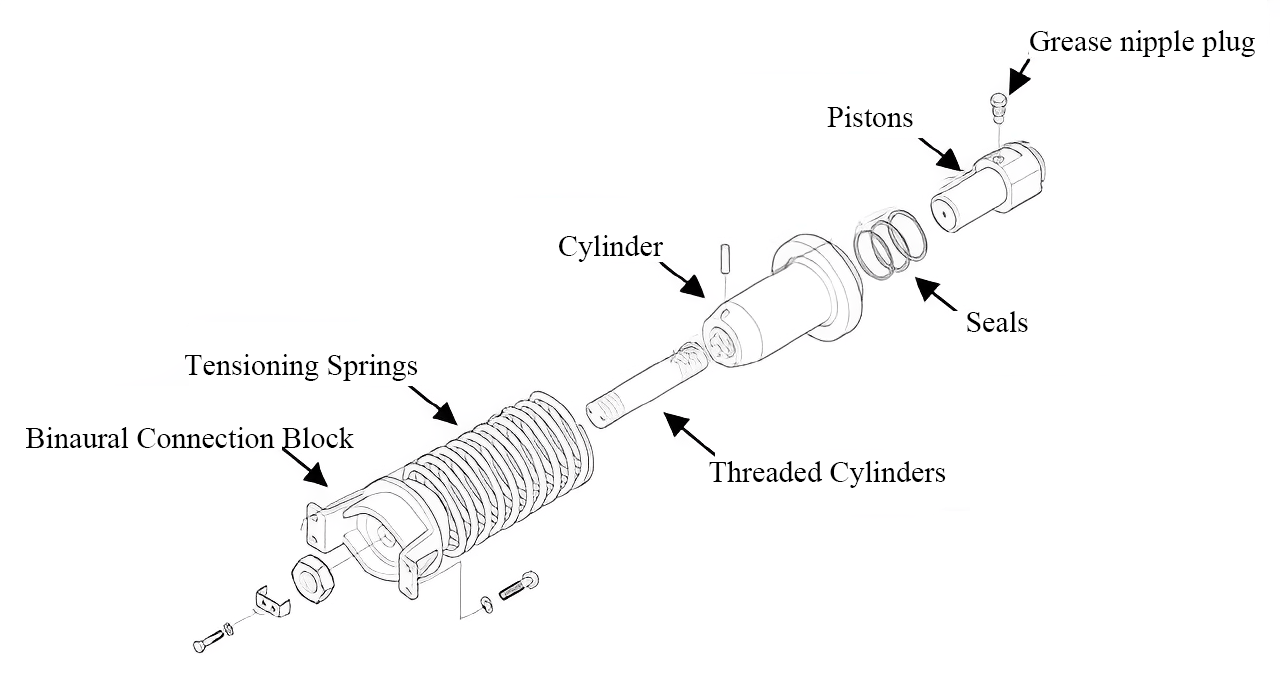

(4.2) Inqubo eqondile yokusebenza yokuqiniswa kwe-hydraulic: ngemva kokuvula i-nameplate kugongolo oluyinhloko ohlangothini olungaphandle lwethrekhi, i-valve yokuhlola ingono yamafutha ingabonakala, uma ukuphakama kokuphakanyiswa kwethrekhi kungu->3cm, sebenzisa isibhamu samafutha. ukubamba ingono ye-valve yokuhlola ukuze igcwaliswe amafutha. Uma ukuphakama kwethrekhi kungu-<3cm, khulula ingono kagrisi ibe ukuphenduka oku-1-2, futhi ithrekhi izoncipha uma kukhona ukuchichima kwamafutha, sebenzisa indlela eshiwo ngaphambili ukuze uphakamise ithrekhi ngesandla ukuze uhlole ukuxega kanye ukuqinisa ithrekhi (enamathiselwe nesithombe esilandelayo ukuze uqinise ingono yamafutha). Okokuqala khulula i-cylinder grease ingono ngokuphenduka oku-1 kuya ku-2, ukukhishwa kwegrisi yesilinda, induku yesilinda ihlehlisiwe. Bese uqinisa i-grease ingono, bese ufaka amafutha amasha, hlola ukuthi ingaphezulu lenduku yesilinda alijwayelekile yini, futhi uma kunesidingo, sebenzisa amafutha ku-cylinder rod, bese uqedela ukugcinwa kokukhuphuka futhi uqinise isilinda (umfanekiso onamathiselwe 3).

(Umdwebo 3 Umdwebo weSchematic of hydraulic tightening (uhlobo lokulungiswa kokuqina kwe-hydraulic)

(4.3): uma i-chassis isetshenziswa njalo, engeza amafutha kanye njalo ezinyangeni eziyisithupha noma ngaphezulu, bese wengeza uwoyela wegiya angu-90# KU-TOP ROLLER kanye nerola yethrekhi (engeza uwoyela ngembobo yepulaki yamafutha emzimbeni wesondo).

(5) Sicela ubheke imanuwali yemiyalo yokusebenzisa i-gearbox yokunciphisa ukuhamba (enamathiselwe).

(6) Sicela ugcine umhlangano we-chassis uhlanzekile, uma ungasetshenziswa, sicela ukubeke endaweni epholile neyomile, ugweme ukukhanya kwelanga nemvula. Ngesikhathi sokusebenza, hlola ukubukeka kwe-crawler chassis nsuku zonke, futhi uhlale ubheka amabhawudi axhumayo esondo lokushayela naku-gearbox nsuku zonke, futhi uwaqinise kusenesikhathi uma kutholakala ukuthi axegekile. Ngesikhathi sokusebenzisa, sicela unake ijubane lomshini, isivinini esiphansi, ungadluli isivinini nokulayisha ngokweqile. Ngemva kokuphuma kwamanzi olwandle noma ane-alkaline, hlambulula ngokushesha ngamanzi ahlanzekile. Ngemuva kokusetshenziswa endaweni yokwakha, hlambulula ngokushesha ukuze usule udaka, sula usimende, uhlale uhlanzekile !!!!

Isikhathi sokuthumela: Feb-08-2024